As in the so called definition of madness. Yes I spent a lot of time yesterday trying to do something expecting it to work. In part because the tutortial I used did not really make full use of SKUs component and group features.

I want to make my hilt fool proof for printing and so I’m dividing them up into shorter sections to print only so high- they are hollow so too tall and there is the risk they will skew. This has to do with Z axis (though my machine has a steel frame- less of an issue unless there is a flaw) and cooling/heating issues. I have a heated plate so that is good.

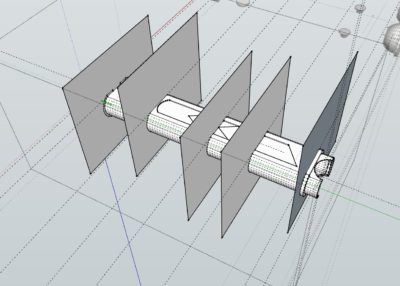

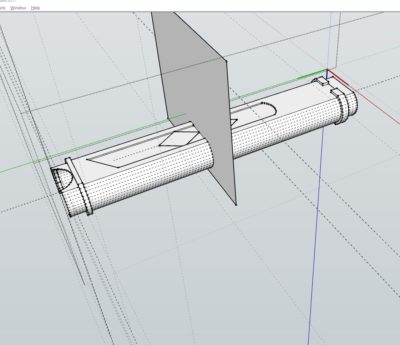

Anyway. to make a slice. Make a square on the green axis make it a component. And then you can merrily place it through your model and it won’t move anything. Then select everything, explode curves, and intersect selection. Then you have the slices in place.

But keep them all as separate pieces before then.

On the right is me using the guide and this shape stretched some interior planes. No idea why. But I didn’t notice until I have all my hilts divided and ready for adding internal support for snapping the pieces together.

So….. I know now. I have had practice now and it means I should., should, be able to do the last tidying of proportions today.

I have been working to the limits of the resolution my printer can manage (apparently 100microns, 0.1mm) but I need to test my machine. PLA at 0.2mm is a bit chunky. I have seen how fine 0.1mm looks on the standard owl model but I don’t know it if was PLA or ABS.

I now have 1.75mm ABS so can test the machine again. And at 0.1mm

I want to make it easier so I’m trying to round all my measurements to full mm so that’s what I’m doing today. Except for anything to do with the emitter. Though I guess I do now know how to cut through a little more easily…

Oh man. What took a couple of days to get “mostly done” for a solid print is taking ages because I want a fancy one that can hold a blade.