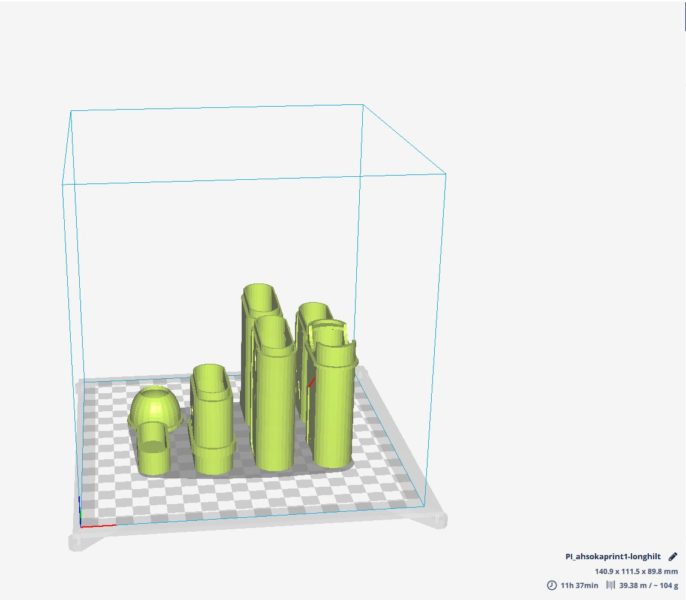

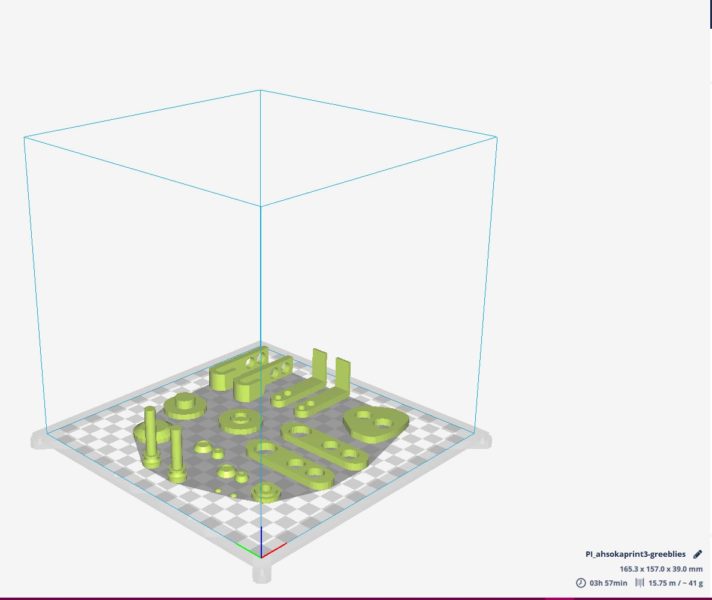

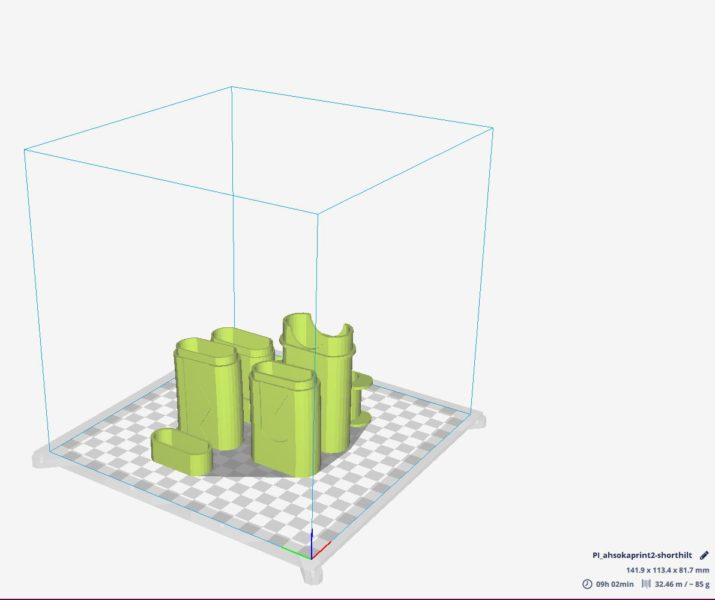

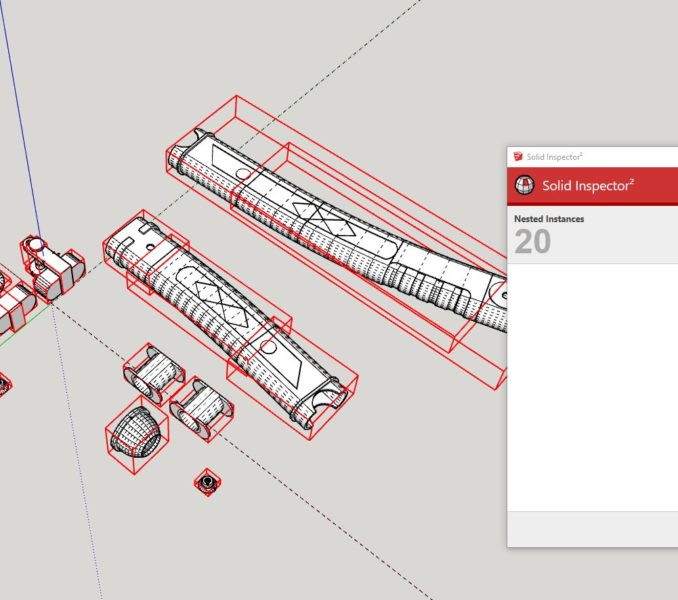

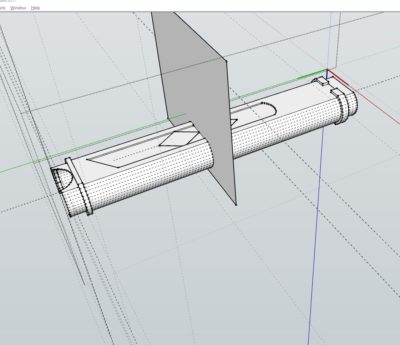

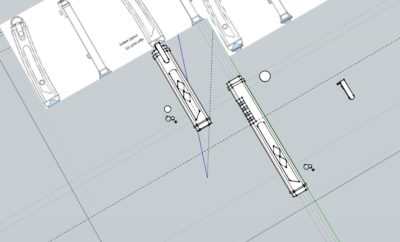

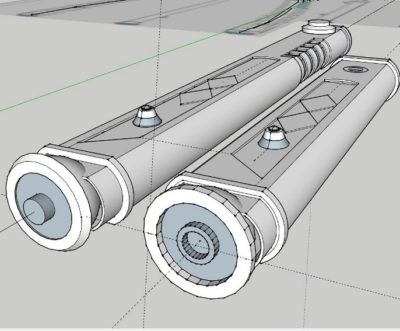

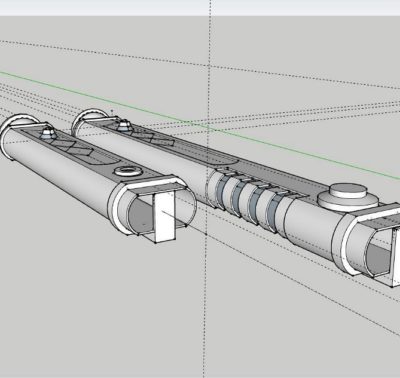

I had left the hilts and greeblies looking good 🙂 But then… today as I was arranging all the parts on a stand in plate… well I found that I needed to cut one hilt section in half, and also find an emitter end cap.

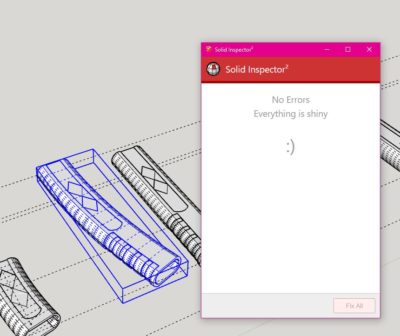

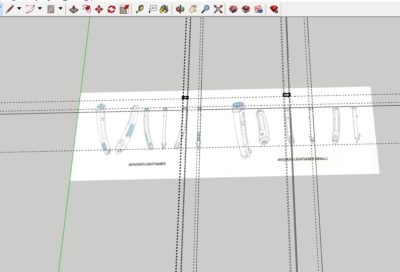

But this is how it all looks now so it should be good 🙂 Okay I know it’s good as I error checked and used Cura 🙂

If you look closely I’m printing at draft quality because I don’t really want to have my printer going for a week. I just don’t trust power/machine combos atm ever 🙂

But it’s really not that bad as I can just sand and acetone wash as planned. So it shouldn’t be extra effort to save a little filament and a lot of time 🙂

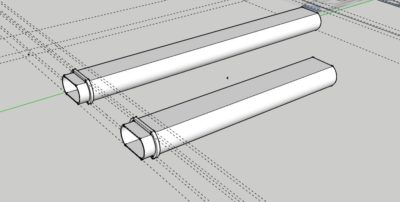

It looks like I only have photos of the previous sets of hilts over here. Yes. I had to rebuild my hilts from scratch as bending the hilts slightly early lead to something being off by about 1mm over the whole length. I managed to do so in a much shorter time frame but… it was still a lot of work. So to find the hilts still needed work today… ugh.

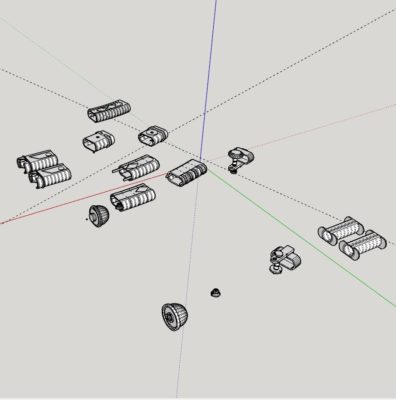

But, yes, all in parts.

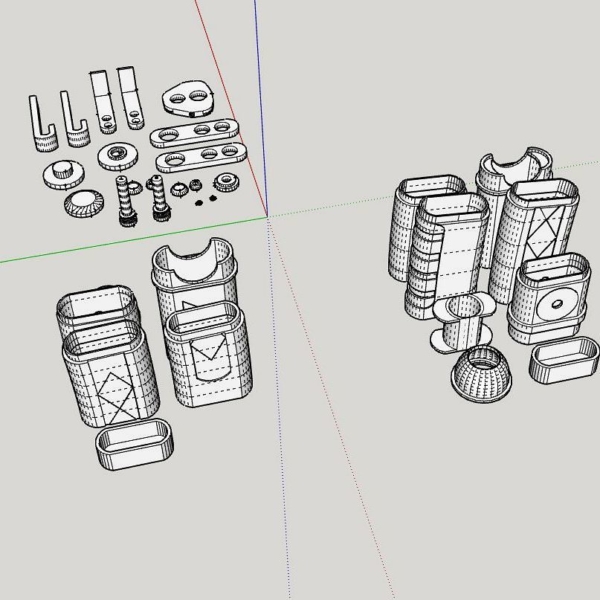

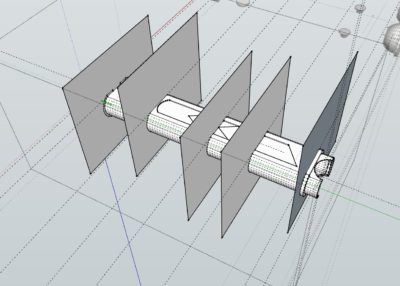

I believe this is actually of my final set 🙂 The emitter got lost so I have put it back in the file here (with all the pieces nested) and in the file at the top (all parts in areas about the size of the plate of my printer) and are in the three files for each print job.

I used LIPID object exporter plugin for Sketchup and opened them in Cura to make sure they were all aligned correctly.

I do really enjoy this. Well most of it. Once the order is sorted and I don’t have to work in the air as such.